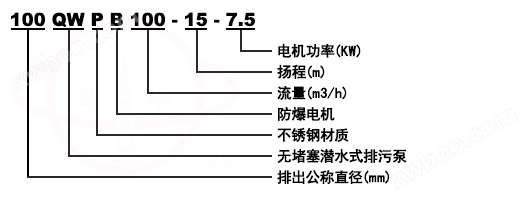

Model Meaning

Product Introduction

The WQ/QW non clogging submersible sewage pump is a type of sewage pump product that has been successfully developed through the joint efforts of our technical personnel and multiple improvements. After testing, all performance indicators have been qualified. It has significant energy-saving effects, anti entanglement, non clogging, automatic installation, and automatic control. It has significant effects in the discharge of solid particles and long fiber garbage.

Flow rate: 7-2400m3/h, Head: 7~60m, etc., designed and manufactured into WL, YW, GW series products with the same energy parameters according to different media and installation methods.

Product Features

1. Adopting a unique single or double blade impeller structure greatly improves the ability of living organisms to pass through, effectively passing through 5 times the fiber material of the pump diameter and solid particles with a diameter of about 50% of the pump diameter

2. The mechanical seal adopts a new type of hard and corrosion-resistant softened tungsten material, which can ensure the safe and continuous operation of the pump for more than 8000 hours.

3. The overall structure is compact, small in size, low in noise, and easy to maintain. There is no need to build a pump room, and it can be filled with water to work, greatly reducing project costs

4. The pump is equipped with a high-precision anti-interference water leakage detection sensor in the sealed oil chamber, and a thermal sensor is embedded in the stator winding to automatically protect the water pump motor.

5. A fully automatic control cabinet can be equipped according to user needs to automatically protect the pump from water leakage, electric leakage, overload, and overheating, improving the safety and reliability of the product.

6. The float switch can automatically control the start and stop of the pump according to the required liquid level changes, without the need for special supervision, making it extremely convenient to use.

The WQ series can be equipped with a dual rail automatic coupling installation system according to user needs, which brings greater convenience to installation and maintenance, and people do not have to enter the sewage pit for this.

8. It can be used within the full head without overloading the motor.

There are two different installation methods, fixed automatic coupling installation system and mobile free installation system.

application

Suitable for the chemical, petroleum, pharmaceutical, mining, paper industry, cement plant, steel plant, power plant, coal processing industry, as well as the drainage system of urban sewage treatment plants, municipal engineering, construction sites and other industries to transport granular sewage and waste. It can also be used for pumping clean water and corrosive media.

working conditions

1. The temperature of the medium shall not exceed 60 ℃; The medium density is 1-1.3kg/dm3.

2. For pumps without an internal self circulating cooling system, the motor part should be exposed to less than one-third of the liquid level.

3. The range of use for cast iron material is from pH 5 to 9.

4. 1Cr18Ni9Ti stainless steel material is suitable for general corrosive media.

5. The altitude of the usage environment should not exceed 1000 meters. If it exceeds, it should be mentioned when placing an order to provide you with more reliable products.

Note: If the user has special temperature and medium requirements, please specify the detailed information of the conveying medium when ordering, so that our unit can provide more reliable products

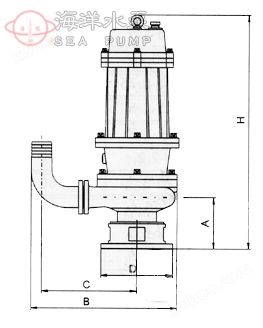

Structure diagram

|

Serial Number |

name |

Serial Number |

name |

Serial Number |

name |

Serial Number |

name |

1 |

The signal line |

6 |

Upper shaft seat |

11 |

Oil water probe |

16 |

Impeller bolt |

|

2 |

Motor wiring |

7 |

motor housing |

12 |

oil chamber |

17 |

impeller |

|

3 |

Junction box |

8 |

stator |

13 |

mechanical seal |

18 |

Sealing ring |

|

4 |

Motor cover |

9 |

Shaft (rotor) |

14 |

Rear cover |

19 |

chassis |

|

5 |

bearing |

10 |

bearing |

15 |

pump body |

Drawing

|

performance parameter

model |

caliber |

internet traffic |

lift |

rotational speed |

power |

efficiency |

A |

B |

C |

D |

H |

automatic coupler |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|||||||

25-7-8-0.55 |

25 |

7 |

8 |

2900 |

0.55 |

45 |

120 |

360 |

225 |

210 |

540 |

|

25-8-22-1.1 |

25 |

8 |

22 |

2900 |

1.1 |

45 |

120 |

360 |

225 |

210 |

540 |

|

32-8-12-0.75 |

32 |

8 |

12 |

2900 |

0.75 |

48 |

120 |

360 |

225 |

210 |

540 |

|

32-12-15-1.1 |

32 |

12 |

15 |

2900 |

1.1 |

45 |

120 |

360 |

225 |

210 |

540 |

|

40-15-15-1.5 |

40 |

15 |

15 |

2900 |

1.5 |

48 |

120 |

360 |

225 |

210 |

540 |

|

40-15-30-2.2 |

40 |

15 |

30 |

2900 |

2.2 |

54 |

120 |

360 |

225 |

210 |

540 |

|

50-20-7-0.75 |

50 |

20 |

7 |

2900 |

0.75 |

51 |

145 |

440 |

275 |

185 |

520 |

GAK-50 |

50-10-10-0.75 |

50 |

10 |

10 |

2900 |

0.75 |

52 |

120 |

250 |

230 |

185 |

520 |

GAK-50 |

50-20-15-1.5 |

50 |

20 |

15 |

290 |

1.5 |

53 |

120 |

250 |

230 |

210 |

564 |

GAK-50 |

50-15-25-2.2 |

50 |

15 |

25 |

2900 |

2.2 |

54 |

145 |

410 |

245 |

205 |

550 |

GAK-50 |

50-18-30-3 |

50 |

18 |

30 |

2900 |

3 |

55 |

155 |

420 |

250 |

260 |

660 |

GAK-50 |

50-40-15-4 |

50 |

40 |

15 |

2900 |

4 |

55 |

140 |

457 |

264 |

310 |

730 |

GAK-50 |

50-25-32-5.5 |

50 |

25 |

32 |

2900 |

5.5 |

55 |

165 |

480 |

285 |

310 |

770 |

GAK-50 |

50-20-40-7.5 |

50 |

50 |

20 |

2900 |

7.5 |

58 |

175 |

480 |

285 |

310 |

770 |

GAK-50 |

65-25-15-2.2 |

65 |

25 |

15 |

2900 |

2.2 |

50 |

145 |

450 |

280 |

205 |

570 |

GAK-65 |

65-37-13-3 |

65 |

37 |

13 |

2900 |

3 |

57 |

165 |

475 |

305 |

260 |

652 |

GAK-65 |

65-25-30-4 |

65 |

25 |

30 |

2900 |

4 |

61 |

170 |

505 |

300 |

325 |

710 |

GAK-65 |

65-30-40-7.5 |

65 |

30 |

40 |

2900 |

7.5 |

56 |

GAK-65 |

|||||

65-35-50-11 |

65 |

35 |

50 |

2900 |

11 |

45 |

165 |

460 |

300 |

350 |

920 |

GAK-65 |

65-35-60-15 |

65 |

35 |

60 |

2900 |

15 |

65 |

165 |

460 |

300 |

350 |

920 |

GAK-65 |

80-40-7-2.2 |

80 |

40 |

7 |

1450 |

2.2 |

59 |

165 |

510 |

330 |

260 |

640 |

GAK-80 |

80-43-13-3 |

80 |

43 |

13 |

2900 |

3 |

70 |

165 |

540 |

330 |

325 |

652 |

GAK-80 |

80-40-15-4 |

80 |

40 |

15 |

2900 |

4 |

61 |

180 |

565 |

330 |

325 |

775 |

GAK-80 |

80-60-13-5.5 |

80 |

60 |

13 |

2900 |

5.5 |

67 |

165 |

565 |

330 |

325 |

775 |

GAK-80 |

80-65-25-7.5 |

80 |

65 |

25 |

2900 |

7.5 |

63 |

180 |

656 |

330 |

325 |

775 |

GAK-80 |

model |

caliber |

internet traffic |

lift |

rotational speed |

power |

efficiency |

A |

B |

C |

D |

H |

automatic coupler |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|||||||

100-80-10-4 |

100 |

100 |

10 |

1450 |

4 |

65 |

220 |

700 |

430 |

420 |

800 |

GAK-100 |

100-100-15-7.5 |

100 |

100 |

15 |

1450 |

7.5 |

68 |

225 |

690 |

420 |

420 |

825 |

GAK-100 |

100-80-20-7.5 |

100 |

80 |

20 |

1450 |

7.5 |

65 |

225 |

690 |

420 |

420 |

825 |

GAK-100 |

100-100-25-11 |

100 |

100 |

25 |

1450 |

11 |

70 |

225 |

690 |

450 |

520 |

940 |

GAK-100 |

100-100-30-15 |

100 |

100 |

30 |

1450 |

15 |

65 |

GAK-100 |

|||||

100-100-35-18.5 |

100 |

100 |

35 |

1450 |

18.5 |

68 |

225 |

680 |

410 |

420 |

970 |

GAK-100 |

125-130-15-11 |

125 |

130 |

15 |

1450 |

11 |

72 |

GAK-125 |

|||||

125-130-20-15 |

125 |

130 |

20 |

1450 |

15 |

75 |

GAK-125 |

|||||

150-145-9-7.5 |

150 |

145 |

9 |

1450 |

7.5 |

76 |

225 |

800 |

510 |

420 |

795 |

GAK-150 |

150-180-15-15 |

150 |

180 |

15 |

1450 |

15 |

69 |

275 |

950 |

610 |

520 |

1060 |

GAK-150 |

150-180-20-18.5 |

150 |

180 |

20 |

1450 |

18.5 |

72 |

250 |

925 |

858 |

520 |

1060 |

GAK-150 |

150-180-25-22 |

150 |

180 |

25 |

1450 |

22 |

78 |

260 |

925 |

585 |

520 |

1060 |

GAK-150 |

150-130-30-22 |

150 |

130 |

30 |

1450 |

22 |

78 |

260 |

925 |

585 |

520 |

1060 |

GAK-150 |

150-180-30-30 |

150 |

180 |

30 |

1450 |

30 |

78 |

GAK-150 |

|||||

150-200-30-37 |

150 |

200 |

30 |

1450 |

37 |

73 |

275 |

1025 |

650 |

520 |

1320 |

GAK-150 |

200-300-7-11 |

200 |

300 |

7 |

980 |

11 |

66 |

290 |

990 |

610 |

520 |

1150 |

GAK-200 |

200-250-11-15 |

200 |

250 |

11 |

1450 |

15 |

64 |

270 |

970 |

600 |

520 |

1120 |

GAK-200 |

200-250-15-18.5 |

200 |

250 |

15 |

1450 |

18.5 |

73 |

290 |

1130 |

715 |

520 |

1130 |

GAK-200 |

200-400-10-22 |

200 |

400 |

10 |

1450 |

22 |

75 |

275 |

1120 |

710 |

520 |

1130 |

GAK-200 |

200-400-13-30 |

200 |

400 |

13 |

14501 |

30 |

76 |

275 |

1120 |

710 |

520 |

1320 |

GAK-200 |

200-300-15-22 |

200 |

300 |

15 |

1450 |

22 |

76 |

275 |

1120 |

710 |

520 |

1130 |

GAK-200 |

200-250-22-30 |

200 |

250 |

22 |

1450 |

30 |

71 |

275 |

1120 |

710 |

520 |

1290 |

GAK-200 |

200-350-25-37 |

200 |

350 |

25 |

1450 |

37 |

71 |

325 |

1080 |

680 |

520 |

1370 |

GAK-200 |

200-400-30-45 |

200 |

400 |

30 |

1450 |

45 |

74 |

330 |

1250 |

780 |

520 |

1370 |

GAK-200 |

model |

caliber |

internet traffic |

lift |

rotational speed |

power |

efficiency |

A |

B |

C |

D |

H |

automatic coupler |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|||||||

250-600-9-30 |

250 |

600 |

9 |

980 |

30 |

78 |

440 |

1100 |

700 |

520 |

1660 |

GAK-250 |

250-600-12-37 |

250 |

600 |

12 |

1450 |

37 |

76 |

440 |

1100 |

700 |

520 |

1660 |

GAK-250 |

250-600-15-45 |

250 |

600 |

15 |

1450 |

45 |

73 |

440 |

1100 |

700 |

520 |

1660 |

GAK-250 |

250-600-20-55 |

250 |

600 |

20 |

1450 |

55 |

73 |

440 |

1100 |

700 |

520 |

1700 |

GAK-250 |

250-600-25-75 |

250 |

600 |

25 |

1450 |

75 |

71 |

440 |

1100 |

700 |

520 |

1750 |

GAK-250 |

300-800-12-45 |

300 |

800 |

12 |

980 |

45 |

74 |

470 |

1305 |

850 |

650 |

1845 |

GAK-300 |

300-480-15-45 |

300 |

480 |

15 |

1450 |

45 |

66 |

470 |

1305 |

850 |

650 |

1845 |

GAK-300 |

300-800-15-55 |

300 |

800 |

15 |

1450 |

55 |

73 |

470 |

1305 |

850 |

650 |

2060 |

GAK-300 |

300-600-20-55 |

300 |

600 |

20 |

1450 |

55 |

73 |

470 |

1305 |

850 |

650 |

2060 |

GAK-300 |

300-800-20-75 |

300 |

800 |

20 |

1450 |

75 |

75 |

470 |

1305 |

850 |

650 |

2120 |

GAK-300 |

300-950-20-90 |

300 |

950 |

20 |

1450 |

90 |

76 |

470 |

1305 |

850 |

650 |

2120 |

GAK-300 |

300-1000-25-110 |

300 |

1000 |

25 |

1450 |

110 |

76 |

500 |

1350 |

875 |

650 |

2220 |

GAK-300 |

300-1100-10-55 |

300 |

1100 |

10 |

1450 |

55 |

73 |

GAK-300 |

|||||

350-1500-15-90 |

350 |

1500 |

15 |

740 |

90 |

87 |

630 |

1533 |

1280 |

700 |

2190 |

GAK-350 |

350-1200-18-90 |

350 |

1200 |

18 |

980 |

90 |

85 |

500 |

900 |

500 |

750 |

2190 |

GAK-350 |

350-1100-28-132 |

350 |

1100 |

28 |

980 |

132 |

84 |

700 |

1616 |

1363 |

700 |

2480 |

GAK-350 |

350-1000-36-160 |

350 |

1000 |

36 |

980 |

160 |

84 |

700 |

1666 |

1413 |

700 |

2590 |

GAK-350 |

400-1760-7.5-55 |

400 |

1760 |

7.5 |

980 |

55 |

83 |

GAK-400 |

|||||

400-1500-10-75 |

400 |

1500 |

10 |

980 |

75 |

86 |

600 |

1650 |

1365 |

780 |

2000 |

GAK-400 |

400-2000-13-110 |

400 |

2000 |

13 |

980 |

110 |

84 |

600 |

1650 |

1365 |

780 |

2280 |

GAK-400 |

400-2000-15-132 |

400 |

2000 |

15 |

980 |

132 |

83 |

GAK-400 |

|||||

400-1700-22-160 |

400 |

1700 |

22 |

980 |

160 |

83 |

630 |

1670 |

1380 |

780 |

2600 |

GAK-400 |

400-1500-26-160 |

400 |

1500 |

26 |

980 |

160 |

84 |

630 |

1670 |

1380 |

780 |

2600 |

GAK-400 |

model |

caliber |

internet traffic |

lift |

rotational speed |

power |

efficiency |

A |

B |

C |

D |

H |

automatic coupler |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|||||||

400-1800-32-250 |

400 |

1800 |

32 |

980 |

250 |

82 |

670 |

1730 |

1440 |

780 |

2850 |

GAK-400 |

500-2500-10-110 |

500 |

2500 |

10 |

740 |

110 |

85 |

900 |

2218 |

1875 |

900 |

2250 |

GAK-500 |

500-2600-15-160 |

500 |

2600 |

15 |

740 |

160 |

84 |

955 |

1968 |

1625 |

900 |

2450 |

GAK-500 |

500-2400-22-220 |

500 |

2400 |

22 |

740 |

220 |

85 |

900 |

2218 |

1875 |

900 |

2520 |

GAK-500 |

500-2650-24-250 |

500 |

2650 |

24 |

740 |

250 |

85 |

1017 |

2198 |

2395 |

900 |

3000 |

GAK-500 |

Use, Inspection, and Maintenance

1. Precautions for use

Pumps are not used in environments with flammable and explosive media, nor are they used to pump flammable liquids.

It is strictly prohibited to impact or roll cables, and it is strictly forbidden to use cables as lifting ropes. When the pump is running, cables should not be pulled randomly to avoid damaging electricity bills, causing corner current accidents, reducing cable sealing, and lowering the insulation performance of the motor wiring cavity.

When using a fixed automatic coupling installation, lift the pump up and down with a lifting chain bolt and handle, and be careful when lifting and placing.

When the pump is placed in water, it should be lifted vertically and not allowed to be placed horizontally on the ground, let alone get stuck in sludge.

A flow control valve should be installed on the discharge pipeline to avoid motor overload caused by excessive flow.

Fault analysis and troubleshooting methods

Fault phenomenon |

Possible causes |

Troubleshooting |

||||||||||

Insufficient flow or no water output |

|

|

||||||||||

Unable to start |

|

|

||||||||||

Stator burnt out |

|

|

||||||||||

Excessive current |

|

|